Description

Tungsten molybdenum alloy paste special spray granulation dryer Jiangsu Bohong drying focus on efficient granulation solutions

Tungsten-molybdenum Alloy Spray Granulation Drying Machine

Tungsten-molybdenum alloys are widely used in aerospace, defense, electronics, and chemical industries due to their high melting point, high strength, excellent electrical conductivity, and corrosion resistance. The size, uniformity, and purity of the tungsten-molybdenum powder directly affect its subsequent processing and performance. Spray granulation drying technology, as an efficient and precise powder preparation method, plays an important role in the production of tungsten-molybdenum alloys.

I. Basic Principles of Spray Granulation Drying Technology

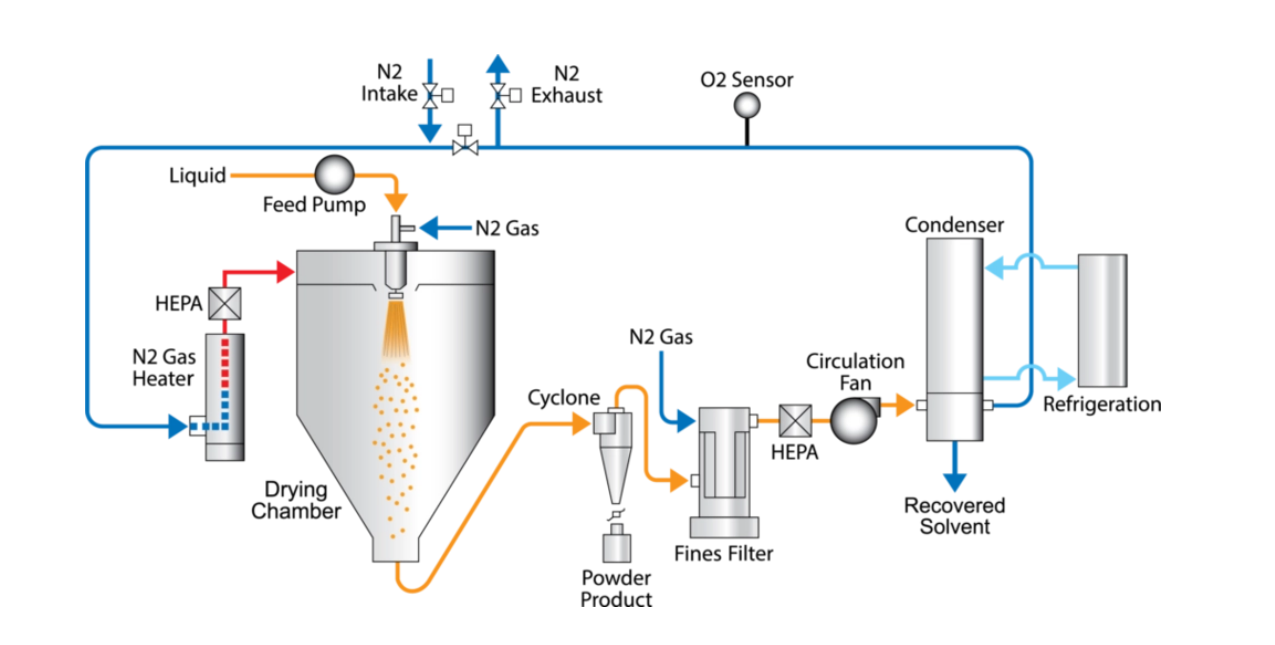

The tungsten-molybdenum alloy spray granulation drying machine produced by Jiangsu Bohong Drying Equipment Co., Ltd. is a device that directly converts liquid or slurry into uniform powder particles. Its working principle is to use a sprayer to atomize the liquid or slurry feedstock into tiny liquid droplets, which are in full contact with the high-temperature drying gas flow to evaporate the liquid droplets quickly, thus forming solid particles. The entire process consists of three key steps: atomization, drying, and granulation.

In the production of tungsten-molybdenum powder, a solution or suspension containing tungsten and molybdenum ions is usually used as the raw material. Spray drying technology is used to process it into shaped, size-controlled powder particles. These powders can be used directly in sintering, smelting, or other high-temperature processing processes.

2. Characteristics of Tungsten-Molybdenum Alloy Spray Granulation Drying Machine

The tungsten-molybdenum alloy spray granulation drying machine can achieve large-scale continuous production, and the equipment parameters (such as the rotational speed of the atomizer, feed concentration, and drying temperature) can be adjusted to control the particle size distribution and shape of the powder.

By spray granulation drying, the tungsten-m

3. Technical Requirements for Tungsten-Molybdenum Alloy Spray Granulation Dryer

The melting point of tungsten and molybdenum is very high (tungsten is 3,410℃, molybdenum is 2,620℃), although the spray granulation drying process does not require reaching the melting point, the dryer material's high-temperature resistance performance is required.

Strong acid or alkali components may be present in the tungsten and molybdenum solution, so the equipment needs to be made of corrosion-resistant materials, such as stainless steel or special coatings, to extend the service life.

To ensure uniform particle size, the design of the nozzle and atomizer is critical. Currently, the use of high-speed centrifugal nozzles or pressure nozzles can achieve control of particle size at the micron level.

4. Application examples of tungsten-molybdenum alloy spray granulation drying technology

In the electronics industry, tungsten-molybdenum powders are widely used to make high-performance electrodes, electron tubes, and targets. Spray granulation drying technology can ensure the purity and uniformity of these powders, meeting the requirements of high-density electronic components.

In the aerospace field, tungsten-molybdenum powders are used as materials for rocket nozzles and high-temperature furnace parts. The powders prepared by spray granulation drying technology can provide higher density and resistance to thermal shock.

5. Trends and challenges

· Optimizing the atomization technology to improve the controllability of powder shape and particle size.

In the future, as nanotechnology and advanced manufacturing technology develop, the application of spray granulation drying technology in the preparation of tungsten-molybdenum alloys will become more widespread. The spray granulation drying machines produced by Jiangsu Bohong Drying Equipment Company not only improve the performance of alloy materials but also promote the development and application of new high-performance materials.

The tungsten-molybdenum alloy spray granulation drying machine, as an important equipment for modern material preparation, combines advanced engineering technology and materials science to significantly improve powder preparation efficiency and quality.

钨钼合金因其高熔点、高强度、优良的导电性和耐腐蚀性能,被广泛应用于航空航天、国防工业、电子工业和化工等领域。在钨钼合金粉末制备过程中,粉末的粒径、均匀性和纯净度直接影响其后续加工和性能。喷雾造粒干燥技术作为一种高效、精密的粉末制备方法,在钨钼合金生产中发挥了重要作用。

江苏博鸿干燥设备公司生产制造的钨钼合金喷雾造粒干燥机是一种将液体或浆料直接转化为均匀颗粒粉末的设备。其工作原理是利用喷雾器将液态或浆状的原料雾化成微小液滴,与高温干燥气流充分接触,使液滴中的溶剂迅速蒸发,从而形成固体颗粒。整个过程分为三个关键步骤:雾化、干燥和造粒。

在钨钼合金粉末制备中,通常使用含钨钼离子的溶液或悬浮液作为原料,通过喷雾干燥技术将其加工成形状规则、颗粒尺寸可控的粉末。这些粉末可以直接用于烧结、冶炼或其他高温加工工艺。

喷雾造粒干燥机能够实现大规模连续化生产,且设备参数(如雾化器转速、进料浓度、干燥温度等)可调节,从而控制粉末的粒径分布和形状。

通过喷雾造粒干燥,得到的钨钼合金粉末粒径分布窄、颗粒形状规则,适合后续的压制和烧结工艺,提高材料的致密度和力学性能。

整个干燥过程在封闭环境中进行,避免了外界污染。特别是在钨钼合金粉末制备中,这一特性有助于保持原料的高纯度,确保合金性能稳定。

钨钼合金的熔点极高(钨为3410℃,钼为2620℃),虽然喷雾造粒干燥过程无需达到熔点,但对干燥机材料的耐高温性能要求较高。

钨钼溶液中可能含有强酸或强碱成分,因此设备需要选用耐腐蚀材料,如不锈钢或特殊涂层,以延长使用寿命。

为保证粒径均匀,喷嘴和雾化器的设计至关重要。目前,采用高速离心喷头或压力喷嘴的方式,能够实现粒径在微米级别的控制。

在电子工业中,钨钼粉末被广泛用于制作高性能电极、电子管、靶材等。喷雾造粒干燥技术可确保这些粉末的纯度和均匀性,满足高精密度电子元件的要求。

在航天领域,钨钼粉末被用作火箭喷嘴和高温炉部件的材料。通过喷雾造粒干燥技术制备的粉末,能够提供更高的致密度和抗热冲击性能。

尽管喷雾造粒干燥技术在钨钼合金领域取得了显著进展,但仍面临一些挑战,例如:

· 如何进一步降低能耗,实现更高的经济效益。

· 开发更加耐高温、耐腐蚀的设备材料。

· 优化雾化技术,提高粉末形状和粒径的可控性。

未来,随着纳米技术和*制造技术的发展,喷雾造粒干燥技术在钨钼合金制备中的应用将更加广泛。江苏博鸿干燥设备公司生产制造的喷雾造粒干燥机不仅能提升合金材料的性能,还能推动新型高性能材料的开发与应用。

钨钼合金喷雾造粒干燥机作为现代材料制备的重要设备,结合了*的工程技术和材料科学,显著提高了粉末制备效率和质量。

Contact:

Mobile:

+86-18651002062Email:

jsbhchina@163.comTel:

0510-86168325Address:

No.188 Xicheng Road,Jiangyin,Jiangsu Province

Hotline

0510-86168325CopyRight © 2022 JiangSu BoHong Brocade Granulation Equipment Co.,ltd All Rights Reserved